The framework of the machine is made of high strength cast-iron and high quality steel plate, it is firm and steady. The machine can run well normally.

The high strength bladed cylinder heat-treated of the machine is made of high quality alloy steel, the channels of inserting blades are processed by a special advanced machine, their lead are standard and the channels are distributed uniformly. The bladed cylinder essembly is balanced in substep before and after assembling, and its accuracy class is not lower than G6.3. The bearings assembled on the bladed cylinder are all from international famous brand.

The discharge roller (roller with rhombic channel) is processed by a special machine, can prevent the hide wavering efficiently while working and ensure discharging smoothly. Its surface is chromed for rust-prevention and duration.

Opening and closing with dampened travel by hydraulic control can ensure beginning and ending of fleshing smoothly;

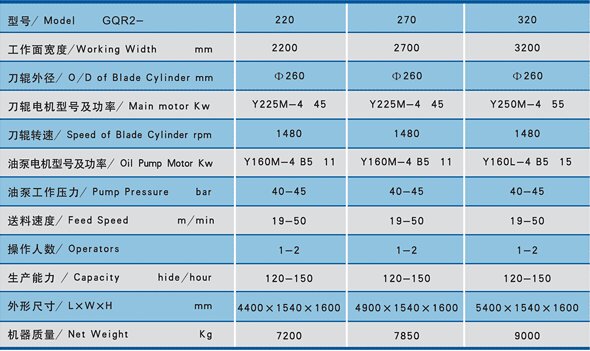

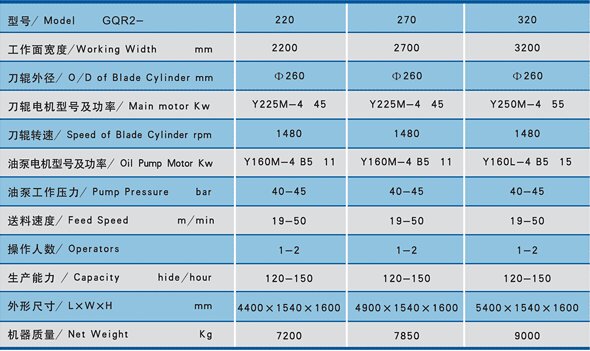

The hydraulically controlled transport with adjustable continuous speed is 19~50M/min;

Adopt the hydraulic supporting system of rubber rod pallet, can completely fleshing in any thin and thick parts of hide without adjusting working clearance. The automatic adjusting thickness is within 10mm.

During the fleshing process, the rubber roller of the machine can open automatically for the hide coming out .this is advantage for installing the machine at a high place.

Double safety device for the operators in working area is consist of a sensitive barrier and 2 dual-linked foot-switches for control closing;

Electric control box sealed are in accordance with the international security standard;

Key hydraulic parts—hydraulic pump and hydraulic motor are all from international famous brand.