High Quality Leather Embossing Roller Machine - GJ2A10-300 Precision Splitting Machine For Cow Sheep Goat Leather – SHIBIAO

High Quality Leather Embossing Roller Machine - GJ2A10-300 Precision Splitting Machine For Cow Sheep Goat Leather – SHIBIAO Detail:

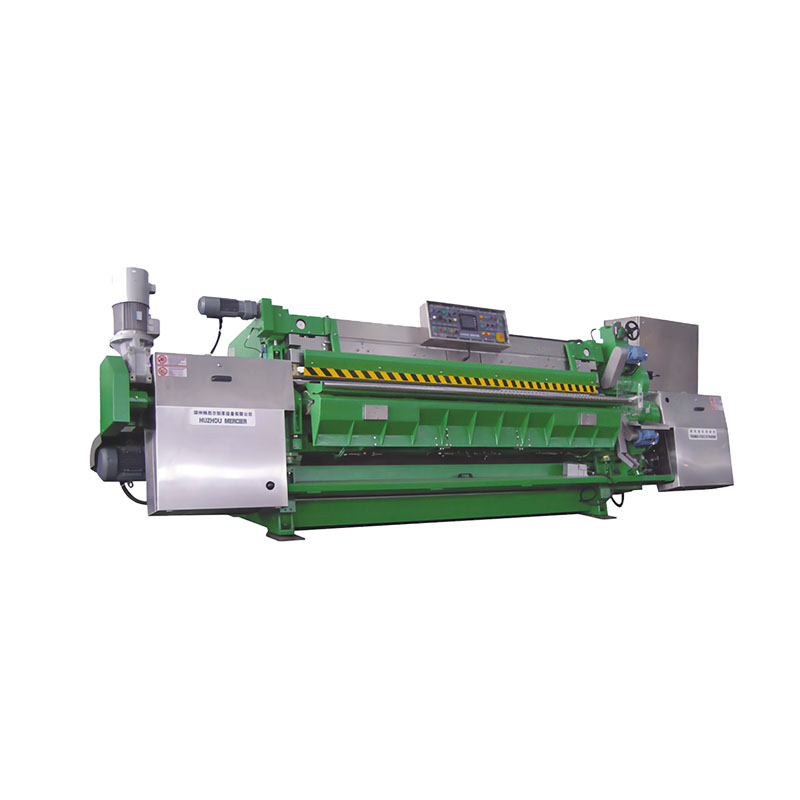

A Splitting Machine Cooperated With Mercier

1. The mini thickness for chrome leather is 0.6mm,precision ±0.1mm, for limed skin is 1mm, precision ±0.2mm.

2. PLC control system, all electric parts with water proof, memory all once stop electricity.

3. Can program the adjustment parameters into a menu, automatically adjusted in place.

4. It has a high reset precision of the feeding roller and cooper roller.

5. The relative position between the nylon roller and feeding roller can be manually adjusted.

6. With the system, rising ,falling and bending of the feeding roller and copper roller, the parameters can be adjusted.

7. The sharpness relative position with feeding roller, cooper roller by digital control.

8. The pressure plate front edge position by digital control.

9. The pressure plate can automatically open and close, convenient to replace and clean.

10. The position of band knife is exact orientation the sensitivity is 0.02mm, and retract quickly.

11. Fixed automatic braking device when the band knife off the position, ensure the safety.

12. Convenient to change the band knife, no need to remove the spline shaft and cardan joint etc.

13. Equipped with horizontal conveying device of a lower skin, can get out the skin from the left or right side, easy to change.

14. Convenient to add automatically move out the skin device when split limed skin.

15. Fixed automatic lubrication device.

|

Technical Parameter |

|||||

|

Model |

Working width (mm) |

Feeding speed (m/min) |

Total power (kW) |

Dimension(mm) L×W×H |

Weight (kg) |

|

GJ2A10-300 |

3000 |

0-42 |

26.08 |

6450×2020×1950 |

8500 |

Product Details

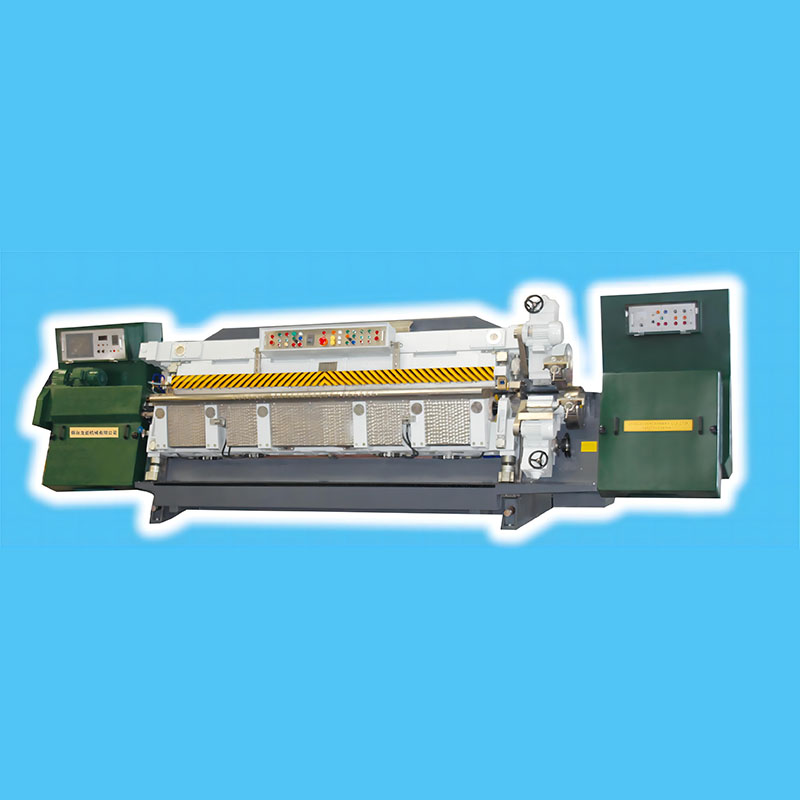

C Normal Type Splitting Machine

For splitting various wet blue skin ,dry finished leather or synthetic leather

1. The mini thickness for wet blue leather is 0.5mm, precision ±0.08mm, finished leather is 0.3mm,precision is ±0.06mm.

2. PLC control system, all electric parts with water proof, memory all once stop electricity.

3. The pressure plate front edge position by digital control.

4. The blade tension device is independent with operate system, the pressure display by pressure meter.

5. The position of band knife is exact orientation the sensitivity is 0.04mm.

6. PLC control the feeding roller rise or down finely.

7. The distance between cooper ring roller and blade is easy to adjust.

|

Technical Parameter |

||||||

|

Model |

Working width (mm) |

Feeding speed (m/min) |

Total power (kW) |

Mini thickness (mm) |

Dimension(mm) L×W×H |

Weight (kg) |

|

GJ2A9-120 |

1200 |

6.4- 32 |

9.96 |

0.3 |

3880×1150×1570 |

2140 |

|

GJ2A9-150 |

1500 |

6.4- 32 |

14.18 |

0.3 |

4180×1150×1570 |

2560 |

|

GJ2A9-180 |

1800 |

7-36 |

15.74 |

0.5 |

5075×1600×1950 |

7200 |

|

GJ2A9-300 |

3000 |

7-36 |

19.54 |

0.5 |

6275×1600×1950 |

8000 |

|

GJ2A9-320 |

3200 |

7-36 |

20.54 |

0.5 |

6475×1600×1950 |

8500 |

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for High Quality Leather Embossing Roller Machine - GJ2A10-300 Precision Splitting Machine For Cow Sheep Goat Leather – SHIBIAO , The product will supply to all over the world, such as: Malawi, Sao Paulo, Philadelphia, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.