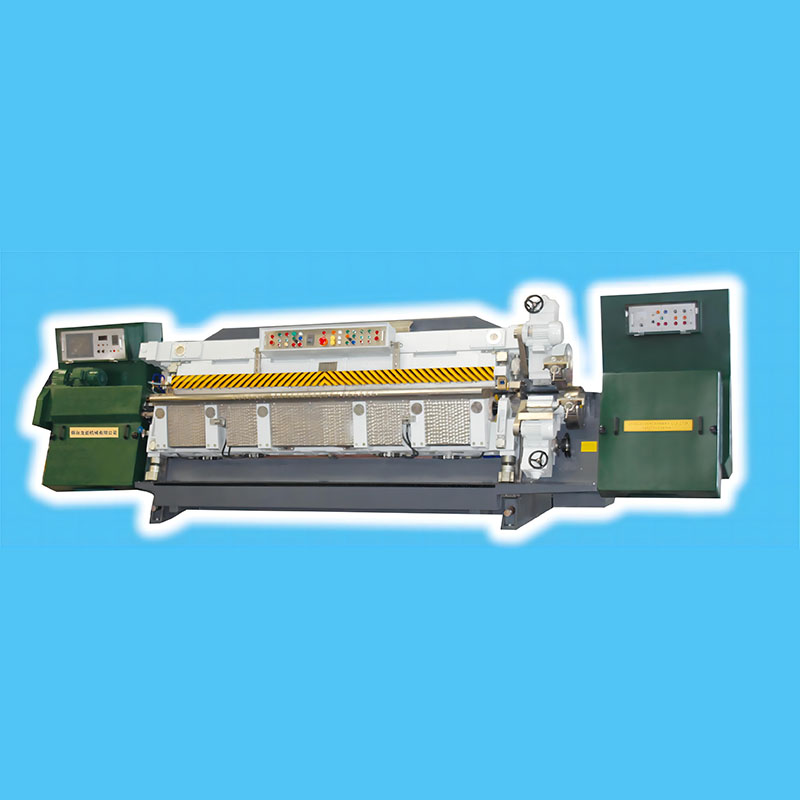

OEM Customized Leather Fleshing Machine For Raw Hides - Vacuum Dryer Machine Tannery Machine For Cow Sheep Goat Leather – SHIBIAO

OEM Customized Leather Fleshing Machine For Raw Hides - Vacuum Dryer Machine Tannery Machine For Cow Sheep Goat Leather – SHIBIAO Detail:

Product Features

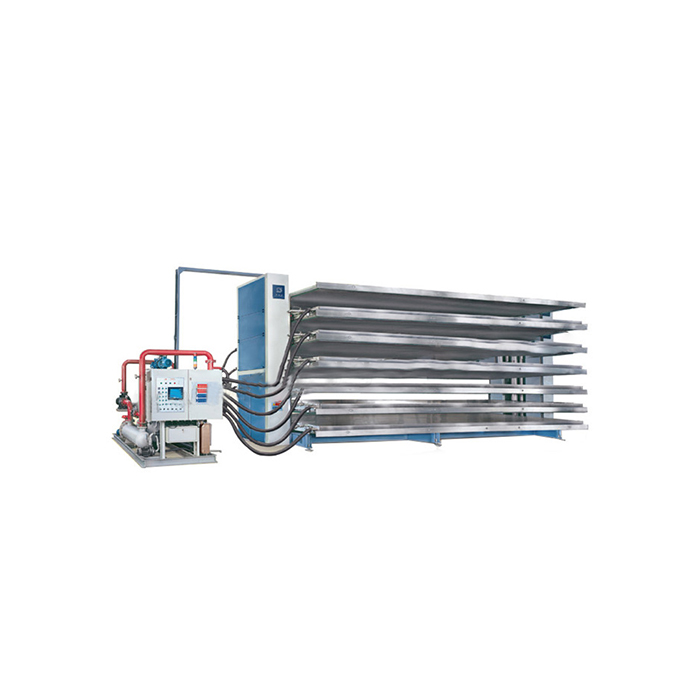

1. Vacuum System

Vacuum system mainly consists of oil ring vacuum pump and roots vacuum booster, can achieve 10 mbar absolute pressure. Under the state of higher vacuum, vapor in the leather can be largely pumped out in a shorter time, so the machine greatly promotes the productivity.

2. Heating System (Patent No. 201120048545.1)

1) High efficient hot water pump: world famous brand, follow international energy-efficiency standards.

2) Hot water channel : special flow channel design.

3) High efficiency in heat conduction and uniform heating, reduces vacuum time.

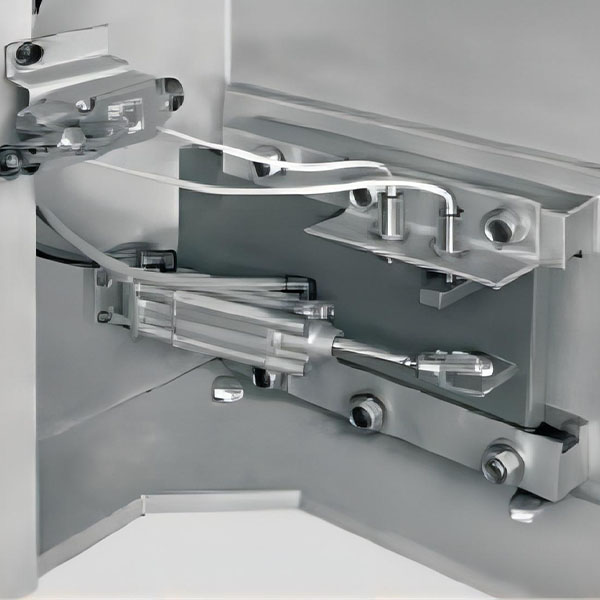

3. Vacuum Releasing System (Patent No. 201220269239.5)

Unique Vacuum releasing system employs tailor-made mechanisms to prevent condensate flowing back to working plate to pollute the leather.

4. Safety System (Patent No. 2010200004993)

1) Hydraulic lock and balance valve :avoid descent of working plates.

2) Mechanical safety device : Air cylinder drive safety block to prevent the descent of its upper plates.

3) Emergency stop, working plate tracking device.

4) Electro sensitive protective device : when machine in movement, worker can not approach to machine, when worker is operating, working plate can not move.

5. Condensating System (Patent No. 2010200004989)

1) Double staged condenser in Vacuum system.

Primary condenser : each working plate is equipped with stainless steel condensers inside its front and back sides.

Second condenser : at upstream of roots vacuum booster.

2) Such equipments of condensers speed up the condensation of vapor, enhance the efficiency of the roots vacuum booster and vacuum pump, increase the suction capacity and heighten the vacuum degree.

3) Others: cooler for hydraulic oil, cooler for vacuum pump oil.

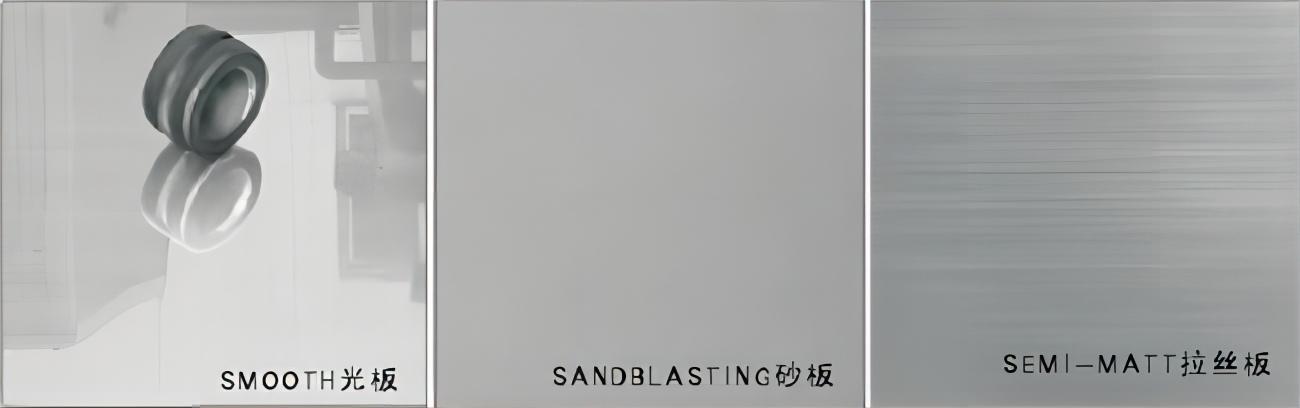

6. Working Plate

Smooth surface, sandblasting surface and semi-matt surface also as customer option.

7. Advantages

1) High quality : using this low temperature dryer machine, the leather quality can be raised substantially, because the leather after drying, its grain face highness is flatten and uniform, it’s felt soft and plump.

2) High leather-obtain rate : while vacuum drying with low temperature, only sucks steam out of leather , and the grease oil can not be lost, the leather can be fully spread and not stringer, and to keep leather thickness not changing.

3) High capacity: due to the working table surface temperature can be lower than 45℃,the capacity is 15%-25% higher than other same machine,

Product Details

Technical Parameter

|

Model |

GGZK |

|||

|

Working Plate size (mm) |

2500×4000 |

3000×4000 |

3000×7000 |

3250×7000 |

|

Plate No |

1P (for laboratory), 2P,3P,4P,5P,6P |

|||

Product detail pictures:

Related Product Guide:

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for OEM Customized Leather Fleshing Machine For Raw Hides - Vacuum Dryer Machine Tannery Machine For Cow Sheep Goat Leather – SHIBIAO , The product will supply to all over the world, such as: Gabon, Swiss, Algeria, During in 11 years, We've participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.