OEM Factory for Belt Embosser - Plate Ironing And Embossing Machine For Cow Sheep And Goat Leather – SHIBIAO

OEM Factory for Belt Embosser - Plate Ironing And Embossing Machine For Cow Sheep And Goat Leather – SHIBIAO Detail:

Product Video

Machine Construction

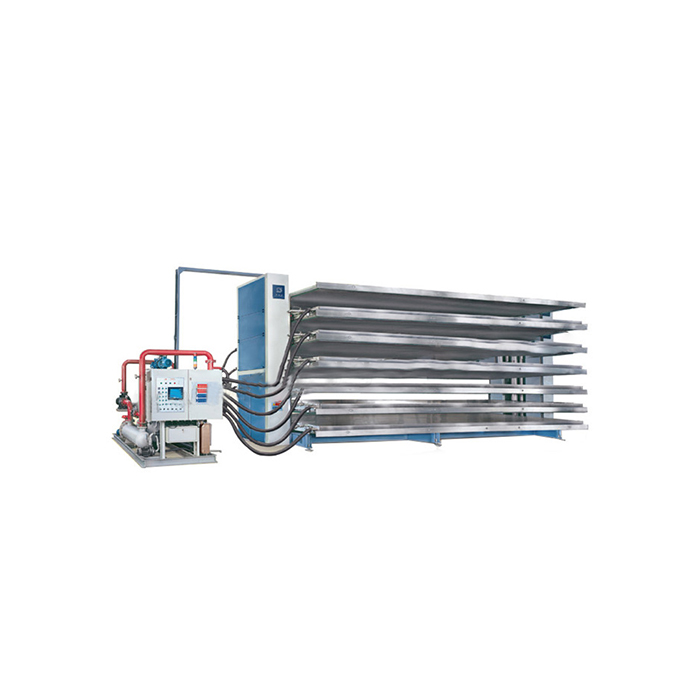

This machine is single cylinder up type hydraulic press , is made up of frame, oil cylinder, ironing table, electric heating plate, hydraulic control system, electrical control system, safety operation and protection part.

The machine adopts a vertical plate frame structure, which is a single cylinder upward moving hydraulic press. Its hydraulic control system and electrical control system are international authoritative brand products. Compact structure, novel and generous shape. The humanized design concept highlights the characteristics of convenient operation, energy saving and high operation efficiency.

Also add filter in Spare Parts: Will add two filter screens and repair tools in spare parts.

Technical Parameters

|

YP1500 |

YP1100 |

YP850 |

YP700 |

YP600 |

YP550 |

|

| Nominal pressure(KN) |

150000 |

11000 |

8500 |

7000 |

6000 |

5500 |

| System pressure(Mpa) |

25 |

26 |

25 |

28 |

||

| Working area(mm) |

1500×1200 |

1370×1000 |

1370×915 |

|||

| Table travel (mm) |

140 |

120 |

||||

| Stroke times (str/min) |

6~8 |

8~10 |

10~12 |

|||

| Pressure holding time (S) |

0~99 |

|||||

| Ironing board temperature (℃) |

Room tep~150 |

|||||

| Motor power(KW) |

37 |

30 |

22 |

18.5 |

15 |

|

| Electric heating power (KW) |

22.5 |

18 |

12 |

|||

| Overall dimension (mm) |

/ |

/ |

/ |

/ |

/ |

/ |

| Weight(≈kg) |

32000 |

24500 |

18800 |

14500 |

13500 |

12500 |

Product Details

Functional Characteristics Such As

1) Frame work Design & material

The machine adopts vertical plate frame structure, frame work is made of Q235B first-grade whole plate material, numerical control cutting, welded under CO2 gas protection, through thermal aging treatment and machining, guarantee the metallicity and strength of extension of the frame.

The parallelism guarantee the pattern and uniform glossiness of embossing leather.

2)Degree of Uniformity

Due to the frame after thermal aging treatment ,guarantee no deformation of long use life. By mechanical processing, upper and lower surface precision within +-0.05,which enable the degree of uniformity.

3)Repetition raising Pressure

The machine has function of repetition of raising pressure, which enhances embossing effect . customer can make the number of repetition raising pressure according to leather technique, can reach to 9,999 at most,

4)Pressure keeping capability

The hydraulic pressure system adopts two intake plug installing system, the valve is airtight. Both of the big and small cylinders keep the pressure .

The GB standard states that keeping 20Mpa status allows decompression 20kg in 10 seconds, but we can reach that decompression 20kg in 99 seconds

5)Energy efficient & heat rising Rate

The heating power is 22.5kW, under constant temperature control. About 35 minutes indoor temperature can reach to 100℃ ,then will be constant temperature,power consumption is relatively small to save energy.

6)Operating life Period

Operating life is directly related to frequency of use and maintenance. Can use for 15 years (8 hours working perday) within the scope of design pressure.

7)Safety Condition

We use electric control system to enable safety. Use approach switch, series circuit of four switch lock .The user can not operate if any one is not connected. Emergency stop switch and flap also guarantee the safety.

8)Special Performance

Manual and auto modes can make changing the plate easily.

Radiator fan can control the temperature of hydraulic oil.

Ultrahigh pressure alarm and security protection.

Filter entrance and return of hydraulic oil.

Filter clogging alarm.

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for OEM Factory for Belt Embosser - Plate Ironing And Embossing Machine For Cow Sheep And Goat Leather – SHIBIAO , The product will supply to all over the world, such as: Lebanon, Angola, Belize, We have more than 10 years experience of production and export business. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We are specialized manufacturer and exporter in China. Wherever you are, please join us, and together we will shape a bright future in your business field!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.